US +1800 764 0366 | Europe & Middle East +44 (0)115 980 3800 | Asia-Pacific: +61 2 7227 5369

Manufacturing Process

Industry-Leading Cylinder Engineering and Manufacturing

Metallurgical innovation is an important part of Luxfer’s history. In 1987, Luxfer introduced its own proprietary formula of 6061-T6 aluminum alloy. Marketed as L6X, this alloy has been optimized to improve durability, fracture toughness and resistance to tearing and cracking. Millions of L6X cylinders in service in over 50 countries have an exemplary record for safety and dependability.

Another significant metallurgical advancement occurred when Luxfer introduced its L7X higher-strength aluminum alloy. Cylinders made from this alloy have the same dimensions as other aluminum cylinders but have up to 50% more capacity because they can be filled to higher pressures.

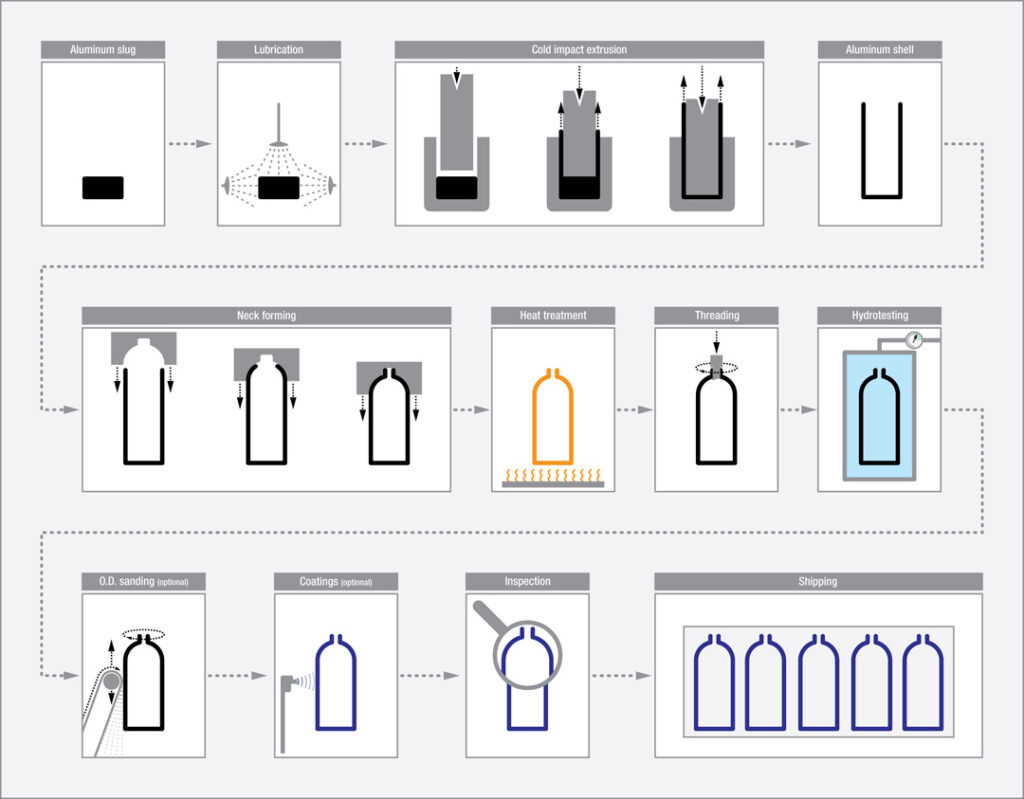

All-aluminum cylinders

A hydraulic ram presses and shapes a solid aluminum billet into a hollow shell, the open top of which is closed and threaded. The newly formed cylinder then undergoes a precisely controlled heat-treatment regimen that adds strength and durability.

After being thoroughly tested to standards established by regulatory agencies, the cylinder is painted or receives a brushed or shot-blasted exterior finish. The result is a seamless, lightweight aluminum cylinder with a consistent wall thickness and naturally corrosion-resistant oxide finish that make it ideal for high-pressure gas containment.

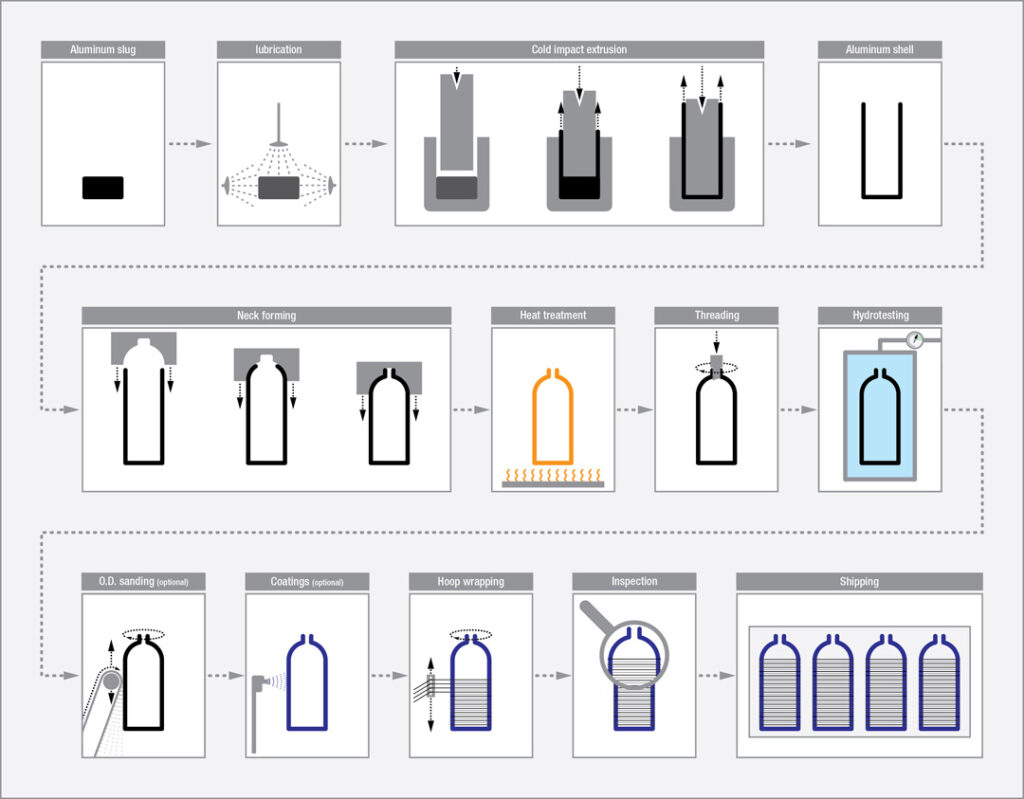

Hoop-wrapped composite cylinders

These cylinders consist of an all-aluminum inner cylinder or “liner” capable of holding the same pressure as a comparably-sized all-aluminum cylinder. The “barrel” or middle cylindrical portion of this liner is wrapped with resin-impregnated fiber (typically fiberglass or aerospace-grade carbon) that reinforces the cylinder walls and enables the finished cylinder to hold higher pressure. The crown and base of the liner are not wrapped.

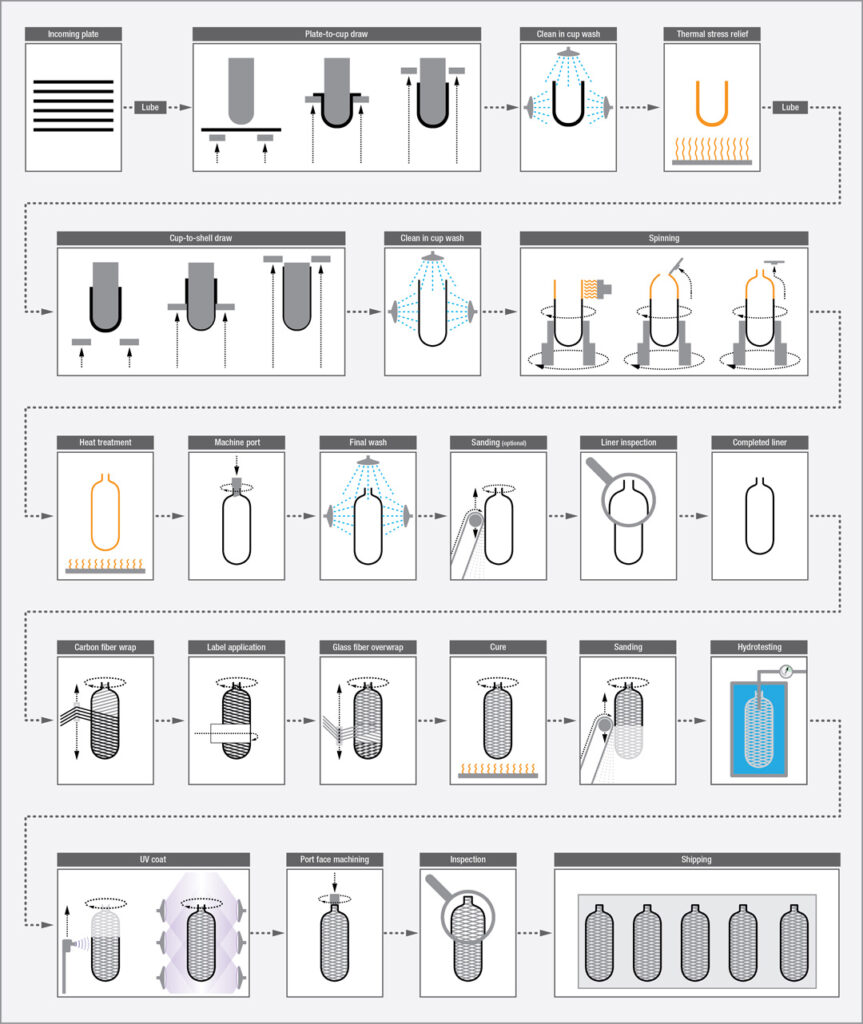

Full-wrapped composite cylinders

A Luxfer-manufactured lightweight aluminum liner is fully wrapped with layers of fiber in a strong, impact-resistant epoxy resin matrix. Fiber (typically fiberglass or aerospace-grade carbon) is applied in proprietary patterns to maximize durability and performance.

The result is an ultra-lightweight, extremely strong composite cylinder capable of operating at higher pressures than standard all-aluminum cylinders. Luxfer full-wrapped composite cylinders are available in a wide range of sizes and capacities from small breathing-air cylinders to very large alternative fuel cylinders. In addition to liners used in Luxfer’s own full-wrapped composite cylinders, Luxfer also manufacturers custom liners for third-party customers.

Make an enquiry

Please fill in this form to contact us for sales, support or general enquiries. Thank you.