US & Asia-Pacific +1 800 764 0366 | Europe & Middle East +44 (0)115 980 3800

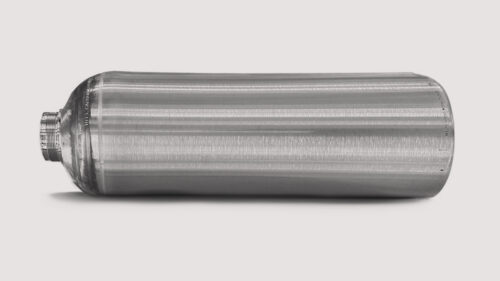

L6X – aluminum type 1 cylinders

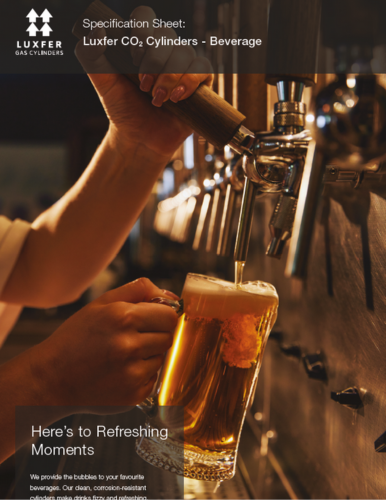

Luxfer is one of the largest manufacturers of aluminum high pressure cylinders, including a broad range of high-quality CO2 and beverage cylinders.

With a quality, lightweight design; a corrosion-resistant, L6X aluminum cylinder and unsurpassed service and support, Luxfer is the superior choice for all your CO2 and beverage cylinder needs.

The Benefits of Luxfer CO2 Cylinders:

Luxfer aluminum cylinders are corrosion-resistant and made from responsibly sourced, low-carbon material.

A brushed aluminum surface requires minimal maintenance, reducing long-term costs and keeping operations running smoothly.

Our aluminum cylinders are lighter and easier to transport than steel, enabling safer transportation and handling.

CO2 - L6X [EU]

| Part Number | Specification | Test Pressure (bar) | CO2 Capacity (kg) | Water Volume (l) | Diameter (mm) | Length (mm) | Weight (kg) | Thread Size |

|---|---|---|---|---|---|---|---|---|

| A868/1/Q | TPED | 250 | 1.07 | 1.43 | 111 | 266 | 2.02 | 25E |

| L3407Z | TPED | 250 | 2 | 2.7 | 117 | 400 | 3.1 | 25E |

| L2906Z | TPED | 250 | 4 | 5.36 | 152 | 470 | 6.3 | 25E |

| L2773Z | TPED | 250 | 5 | 6.7 | 152 | 565 | 7.35 | 25E |

| L2815Z | TPED | 250 | 6 | 8.04 | 160 | 600 | 8.55 | 25E |

| L2711Z | TPED | 250 | 10 | 13.4 | 204 | 650 | 14.9 | 25E |

| L3105Y | DOT | 207 | 10 | 13.4 | 204 | 594 | 10.3 | 1.125"x12UNF |

Support and downloads

Make an enquiry

Please fill in this form to contact us for sales, support or general enquiries. Thank you.